How To Use VLM Encapsulation Carpet Cleaning Methods For Your Business with Orbot Vibe

Oscillating pad machines, particularly the Orbot Vibe, have revolutionized the carpet cleaning industry with their versatility and effectiveness. This comprehensive guide explores the benefits of Very Low-Moisture (VLM) cleaning methods and how they can help maximize business profits.

Understanding VLM and Encapsulation Cleaning

Very Low Moisture (VLM) or encapsulation cleaning effectively cleans carpets using minimal water and specialized carpet cleaning chemicals. This process encapsulates soil particles, which can then be easily vacuumed away, leaving carpets clean and dry quickly.

Benefits of VLM Cleaning:

- Fast drying times (30-45 minutes)

- Reduced water usage

- Effective soil removal

- Extends carpet life

- Ideal for commercial settings, especially glue-down carpets (CGD)

The Orbot Vibe: A Game-Changing Machine

The Orbot Vibe is one of the best oscillating pad machines on the market, offering excellent performance and versatility. To optimize its performance, using complementary tools like a stair tool can enhance accessibility and cleaning on multiple surfaces.

Key Features of the Orbot Vibe:

- Adjustable weight system for different cleaning situations

- Versatile cleaning capabilities (carpets, hard floors, stone, concrete, LVT, and hardwood)

- High-quality construction with laser welds and powder coating

- Easy to transport and maneuver with large wheels for stair navigation

- Compatible with various pads and accessories

- Detachable cord for tangle-free operation

- Convenient momentary cord for reducing downtime

Maximizing Profits with VLM Cleaning

Incorporating VLM cleaning methods into your business can:

- Increase efficiency and productivity

- Expand your service offerings

- Reduce equipment and chemical costs

- Improve customer satisfaction with faster drying times

- Access new markets, such as commercial and healthcare facilities

Best Practices for VLM Cleaning

To achieve optimal results with your Orbot Vibe and VLM cleaning methods:

- Always pre-vacuum thoroughly to remove dry particulate matter

- Use high-quality encapsulation chemicals

- Adjust the machine's weight according to the carpet type and soil level

- Take extra time in heavily soiled areas and traffic patterns

- Follow up with a clean bonnet for extraction

- Educate customers on the benefits of VLM cleaning and manage their expectations

Advanced Cleaning Techniques

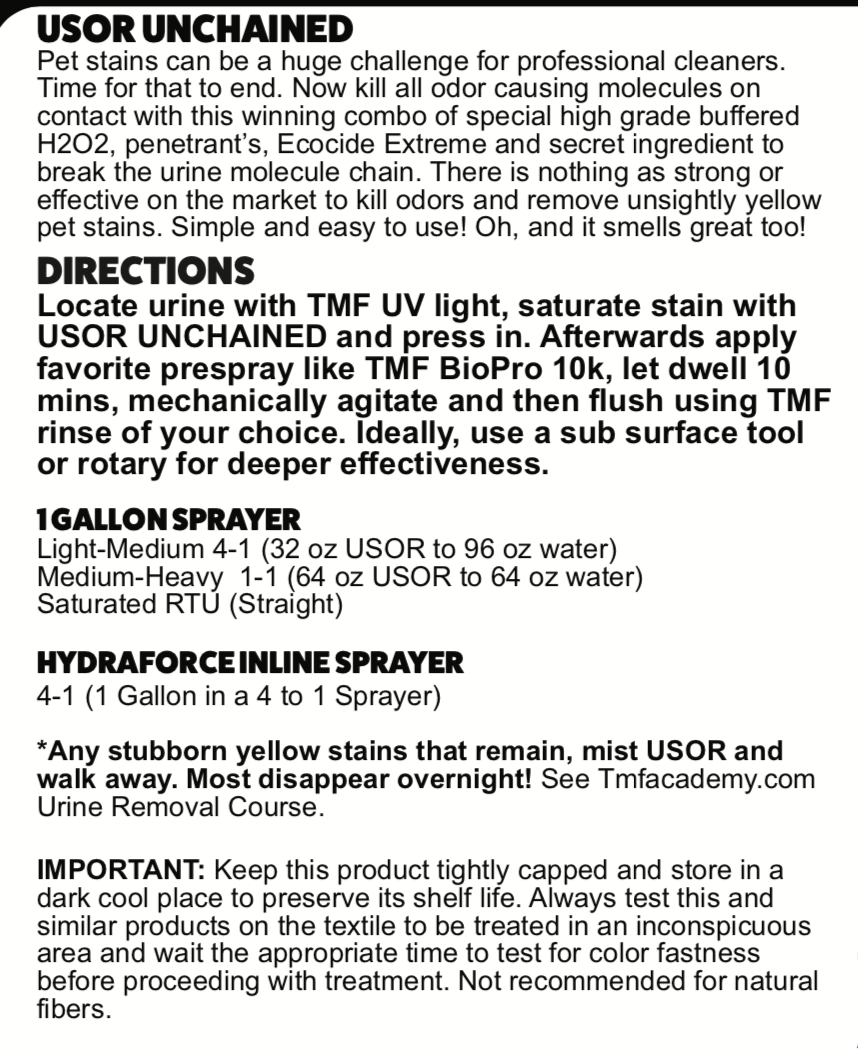

UV Light for Urine Detection

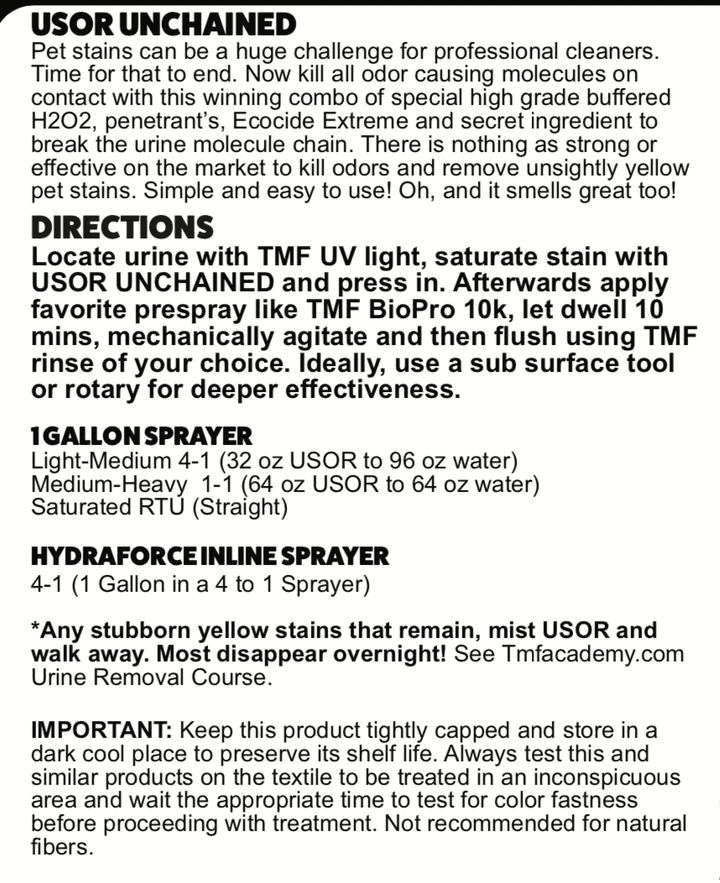

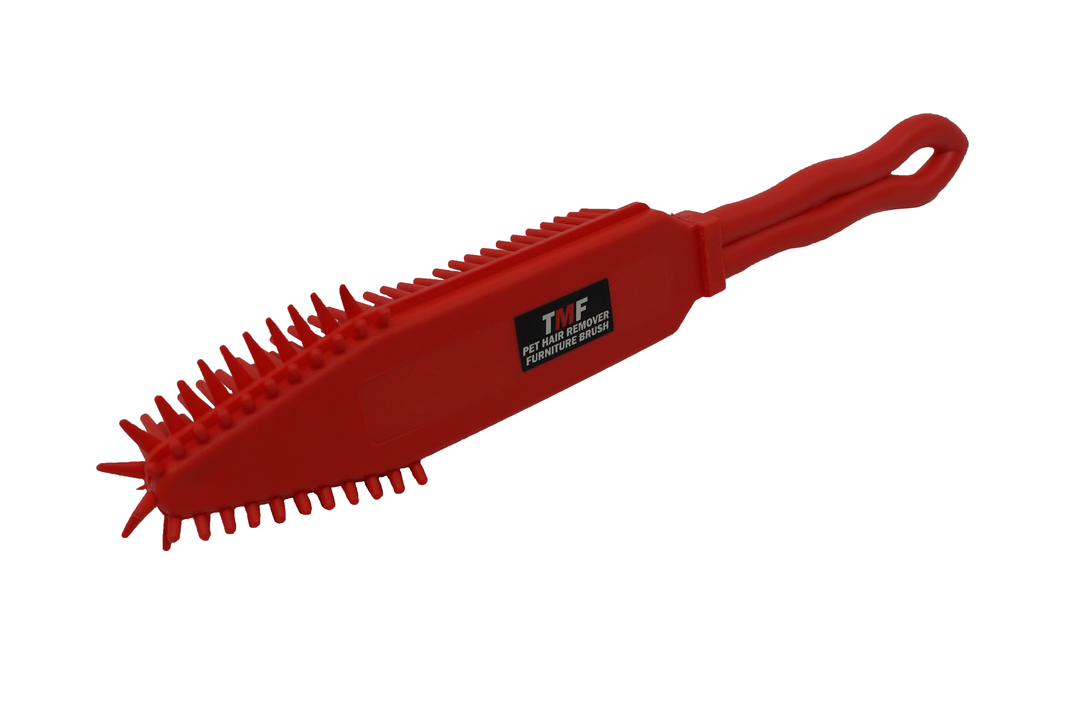

Utilize a UV light, such as the TMF black light, to detect urine stains effectively. This tool can help you charge appropriately for urine treatments and ensure thorough cleaning.

Specialized Products

Use products like Super Cap Unchained for urine treatment, which breaks down urine molecules without affecting the encapsulation polymers.

Crystallization Process

High-quality encapsulation products crystallize as they dry, improving carpet appearance and allowing for easy vacuuming of trapped soil particles.

Business Support and Training

When investing in an Orbot Vibe, look for providers that offer carpet cleaning training, comprehensive training courses, and ongoing customer support.

Return on Investment

While the initial cost may be higher, focus on the value and potential earnings from using quality equipment:

- One or two commercial jobs can often pay for the machine

- Improved efficiency leads to more jobs and higher profits

- Professional results lead to repeat customers and referrals

Frequently Asked Questions

Is VLM cleaning as effective as hot water extraction?

While hot water extraction is still considered more thorough, especially for certain types of commercial carpets, VLM cleaning is highly effective for maintenance cleaning and can extend the time between deep cleanings.

How versatile is the Orbot Vibe?

The Orbot Vibe can clean various surfaces, including carpets, hard floors, stone, concrete, LVT, and hardwood, making it a versatile tool for diverse cleaning needs.

How important is pre-vacuuming in the VLM process?

Pre-vacuuming is crucial as it removes dry particulate matter, allowing the VLM process to focus more effectively on embedded soils and stains.